Why microseismic monitoring is not dead (yet): Managing Expectations

The original article was published in LinkedIn on Jan 8, 2017.

As the industry slowly recovers from an unprecedented downturn, it has become clear that the U.S. unconventional plays have become a key player in the worldwide upstream sector. And with it, there’s a cohort of technologies that should enable a leap in ROIs and unlock these resources across the world through a better understanding of what is at stake.

As 2017 opens, it felt it was a good time to reflect on the place “passive monitoring” currently has in the O&G industry, and why it seems it will (or at least, should) play a growing role in the exploration and improvement of unconventional resources.

The Growing Importance Of "Passive Seismic"

First and foremost, some figures: there has been 7 sessions on passive seismic during this year’s SEG Annual Meeting, omitting the papers that dealt with acquisition and that were not scheduled in passive-seismic dedicated sessions (such as Jia et al. [2016]’s on surface patch acquisition design) and the special session on Induced Seismicity and two dedicated after-event workshops. This proves, if need be, how passive seismic in general – and microseismic monitoring in particular – has become a central geophysics topic, at least in North America.

Yet, microseismic monitoring has suffered from the downturn to a great extent, as operators (and particularly the stimulation and reservoir engineers in the room) have been steering away from it. Indeed it wouldn’t give them more information than they already had. The promises microseismic monitoring held haven’t been met, and the industry failed at managing non-specialists’ expectations.

In other words: microseismic monitoring has been way oversold.

Understanding the Physics: Do Not Overlook The Hydraulic Fracture!

The past couple of years have seen a growing body of researchers trying to better understand what drives microseismicity. It is now clear that it isn’t as simple as was initially thought: there is a plurality of mechanisms that are not clearly understood or even known (aseismic slip, plasticity, etc.), and many of these may have a different weight in the overall process depending on the basin or even where we stand along a lateral. In fact, because the primary goal was to sell a value proposition, most companies have overlooked what should be at the heart of our activity: trying to understand the many observations we have.

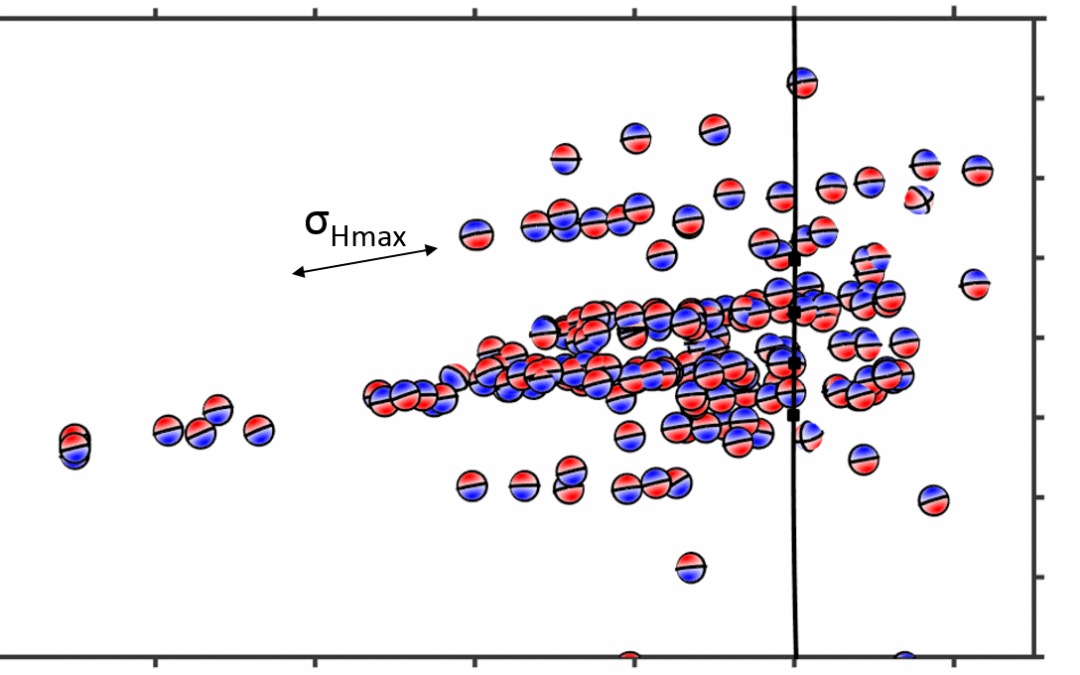

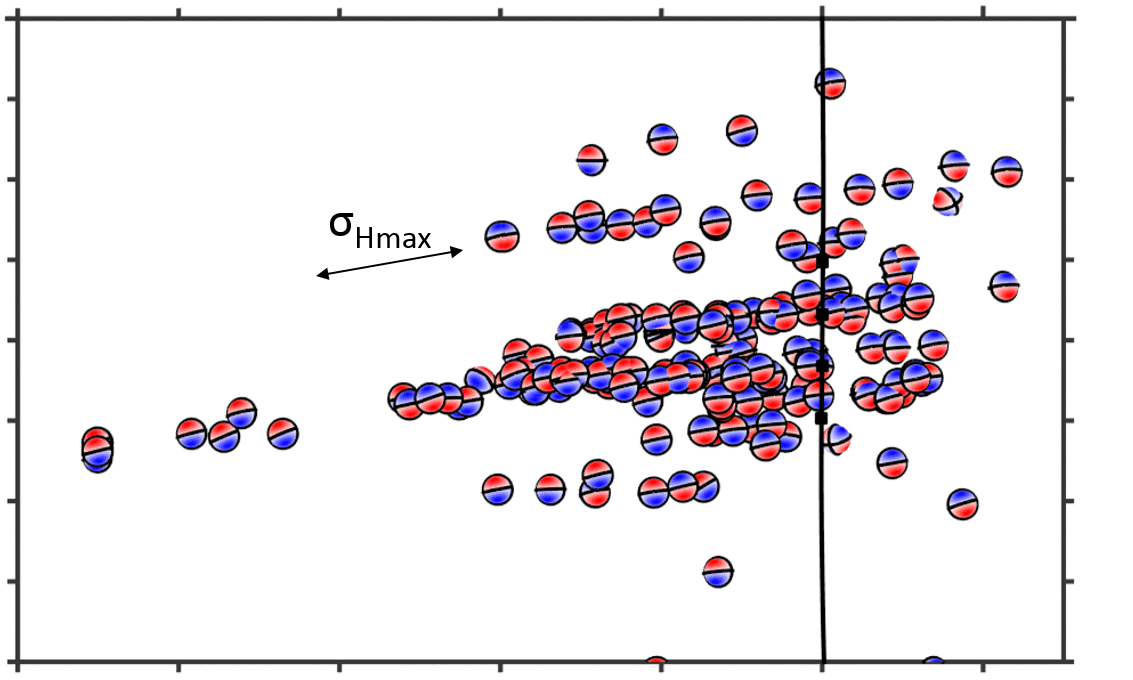

First articles published on hydraulic fracture monitoring hypothesized that microseismic events would be generated by mode I mechanisms (i.e. the opening of said fracture); yet, the ratio of S- to P-wave amplitudes clearly indicated those events where caused by shear failure rather than tensile failure [Pearson, 1981]. Further to this, the energy released via seismicity is infinitesimal when compared to the energy input for hydraulic fracture creation and propagation [Goodfellow et al., 2015].

Along the same line of thought, take the concept of SRV (Stimulated Reservoir/Rock Volume) as defined by geophysicists (and not reservoir engineers). It was thought to be a measure of the contacted reservoir, thus providing information on productivity of a given well. Yet it has proven to be particularly off is many instances – take a look at [Cipolla and Wallace, 2014] for a detailed and fascinating discussion on this topic.

This proves, if need be, that microseismicity is the expression of the interaction between the hydraulic fracture propagation and the formation – and not a measure of the hydraulic fracturing processes per se.

Admitting Our Ignorance

The O&G industry has been pushing service companies and specialists to rationalize microseismicity and to make it “an engineering tool” able to provide qualitative information on the stimulation and the resulting production, all of it as a standalone measurement.

I would claim that, given our (current) limited understanding of the mechanisms driving microseismicity, it is unreasonable to build complex, engineered interpretations solely using microseismic information. Ongoing research will however strengthen our understanding, up to a point where, maybe, we will be able to use it to its full potential.

Accepting What Microseismicity Is NOT

Accepting that microseismicity (1) isn’t self-sufficient and (2) that it needs to be integrated with other measurements (such as image logs to infer fracture density, near-wellbore acoustic images of fractures, seismic reservoir characterization, etc.) into a single framework (a full-blown geomechanical model) should highlight that microseismic monitoring remains the only far-field, real-time measurement of hydraulic stimulation.

As such, it should definitely be a need to have rather than a good to have.

References

Cipolla, C., and J. Wallace (2014), Stimulated Reservoir Volume: A Misapplied Concept?, in SPE Hydraulic Fracturing Technology Conference, edited, Society of Petroleum Engineers, The Woodlands, Texas, USA.

Goodfellow, S. D., M. H. B. Nasseri, S. C. Maxwell, and R. P. Young (2015), Hydraulic fracture energy budget: Insights from the laboratory, Geophysical Research Letters, 42(9), 3179-3187, doi: 10.1002/2015gl063093.

Jia, T., C. Regone, J. Yu, A. Gangopadhyay, R. Pool, C. Melvin, and S. Michell (2016), Microseismic surface patch array: modelling and velocity estimation using ambient noise, in SEG Annual Meeting, edited, Society of Exploration Geophysicists, Dallas, TX, USA.

Pearson, C. (1981), The relationship between microseismicity and high pore pressures during hydraulic stimulation experiments in low permeability granitic rocks, Journal of Geophysical Research: Solid Earth, 86(B9), 7855-7864, doi: 10.1029/JB086iB09p07855.

* Special thanks to Mr. Roux who shared this article on our blog.